Salesforce is the world’s leading CRM, known for its flexibility and reliability in automating processes and increasing the sales and sales efficiency of companies. Beyond the CRM, the Salesforce platform can also encompass many more business functions, such as customer service, customer & partner portals, marketing, and more. The open APIs of the platform also enable the integration of mission critical systems like ERPs and accounting.

As a manufacturer, you may be currently using it, or are in the process of looking to implement Salesforce for manufacturing projects. You may be looking for best practices to maximize its benefits for your company, or have questions on how Salesforce for the manufacturing industry can impact your business. The following is an expanded version of a discussion with manufacturing and digital transformation expert Louis-Nicolas Hamer. He has over 20 years of experience in Fortune 500 and startup companies, including in the telecom, commercial/industrial controls and energy industries. He is also knowledgeable with the diversity of go-to-markets and channels used by manufacturers, from direct, to resellers, distributors, value-added resellers (VARs), specifiers, etc. In the studio we asked him what are the key concepts, mindset, best practices, To Do’s, Can’t Miss, and Must Avoid related to the topic of Manufacturer CRM with Salesforce. So, let’s get started!

If you’re more the YouTube type, you can watch this conversation, which covers the rest of the items discussed in this blog post.

Forecasting

Sales forecasts and proper financial planning are essential for all businesses in all industries. However, it plays an even bigger role for manufacturers. The entire management of the supply chain, inventory and cash flow can be impacted by poor or the lack of clear sales forecasts.

Considering the earth-shattering levels of disruption to the global supply chain since Covid, accurate forecasting has become even more critical for all Salesforce for Manufacturing projects.

With Salesforce,sales forecasts can be updated in real-time by your sales team, and weighted based on the probability % of each Opportunity to close. And each Opportunity can be detailed with the exact product, components or assemblage that is being sold.

All of this information can be pushed or synced with your Operations teams, which can adjust their planning based on accurate and up-to-date data. This enables them to increase or decrease provisioning / purchasing of materials and components, to get to the right levels of inventory based on what is coming down the pipeline.

Of all the capabilities of Salesforce, forecasting, as simple as it sounds, may actually be the feature that can have the biggest positive effect for manufacturers for whom supply chain and inventory is the name of the game.

Integration with your ERP

How do you get sales and operations to work better together? How do you enable your customer service to give the right information to all customers about their orders or deliveries? How do you give your e-commerce customers the data they need to buy the right quantity at the right time?

The answer to these questions and many more is to start by integrating your ERP system to your Manufacturer CRM. Conceptually, this is the best way to break the silos that exist within your organization’s most important business functions.

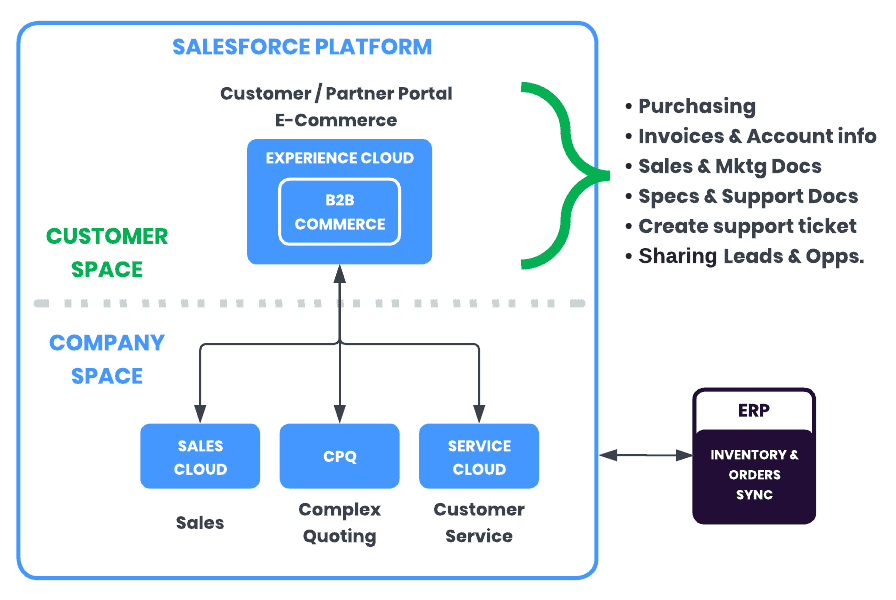

Typically, manufacturing companies that use the Salesforce platform will use it to manage sales, customer service, partners & channel portals, marketing, and e-commerce directly from the platform. In some instances, some of these applications may also use 3rd party systems. The silo that can persist is between all of these customer-facing business functions, and operations.

By implementing a solid real-time connection between Salesforce and your ERP, you break this silo, and unlock a world of new possibilities to improve customer experience and operational efficiency.

Sales pushes forecast information to operations. Customer service provides inventory and shipping information to prospective or existing buyers. Customers and distributors can access up to date information about inventory, orders, documentation and more on a dedicated portal or e-commerce. And that’s just the start.

Channel Management

As a manufacturer you may be selling through a wide variety of channels that can include direct, to resellers, distributors, retailers, value-added resellers (VARs), specifiers, etc.

Each of these channels comes with its own set of practices and particularities, such as different pricing, discounts and multipliers per account, available products, specific documentation, etc.

One of the best ways to ensure every stakeholder accesses their own specific set of benefits or contract commitments, is to use a dedicated portal. In the Salesforce-verse, Experience Cloud is the module used to create portals.

From there you can customize every feature to your target customers, including the entire layout of the portal, what they can access after login, what information you share with them, and what information they can share with you, including sharing Leads with your partners (if that is part of your business model).

You can also nest the Salesforce e-commerce solution B2B Commerce within your Salesforce Experience Cloud portal, to streamline purchasing for customers and partners that want it or need it.

From the previous section on ERP integration to here, you’re starting to see the full technological stack that you can use to really streamline customer experience and internal processes… From Operations to Sales and back…

User Adoption

User adoption is key to getting the most out of your CRM. And here, let’s be honest, sometimes manufacturing is not the industry that everybody thinks of when referring to “early adopters” of anything.

If we set aside the topic of organizational culture, and focus on what the solution itself can do to fuel adoption, the customizability of Salesforce is the advantage that manufacturers can use to maximize adoption and reduce apprehensions.

A new tool, or solution, like a CRM, can be easy to approach, intuitive and adapted to your business and your teams if you take the time to customize it for the target audience: your users.

Salesforce for the manufacturing industry starts off with a UI that is easy to understand and navigate. But on top of it, you can tailor everything you see (objects, fields, Lightning components, dashboards, etc.) to design the user experience that will foster both adoption and efficiency gains.

This is where many organizations miss the boat… You have spent time properly designing the company website, haven’t you? To optimize navigation, and make sure key information is front and center for visitors to see. “They can’t miss this!” was said in a meeting, I’m sure.

Did you know that you should also optimize the placement of information and components in your Salesforce. The platform is so flexible that you can literally A/B test layouts with your users to see which ones really result in the usage that you expect.

This might be one of the most underused capabilities of Salesforce. You can tweak any layout in seconds and gather feedback from your users to see which one they prefer in terms of intuitiveness and efficiency (saving time everyday by the optimal placement of features to minimize clicks and surface key information where it is needed in the sales or customer service process, etc.).

One thing is for sure: Manufacturing Cloud Salesforce is ready to adapt itself to how you want to run your business.

Let’s take a deeper dive into four subtopics of channel management in the B2B space to see how Salesforce for Manufacturing projects can help you navigate the complexities of your B2B world.

1. Managing different sales cycles

Sales cycles in B2B companies can vary greatly. An existing distributor may make a re-order on your dedicated e-commerce in seconds, while another customer might take 6 months to finally sign the contract for a complex hardware system with installation services included.

The product or solution sold, the specification process, the type of buyer, the number of people involved in the decision, and the intermediaries involved in the Opportunity are all factors that can play into the length and the steps of sales cycles.

Salesforce CRM allows you to navigate this complexity by giving your sales teams various tools to reach the desired outcome.

If the sales journey is meant to differ greatly depending on the type of customer (direct vs. distributor vs. VAR, etc.) or the product or solution sold, you can use customized sales paths adapted to each context, with different stages, assets and approvals. Your sales forecast can also be tailored to accurately reflect the probability of close based on these stages and the type of sale you are dealing with.

Over time, you can incrementally streamline each sales path with additional templates and automations to shorten the sales cycles, or improve the sales experience for the buyer.

If you are selling through a portal (using Salesforce Experience Cloud, B2B Commerce, etc.), the same principles apply.

2. Give more and get more with your partners

Continuing on the topic of enabling the partner channels of manufacturing businesses, all organizations should ask themselves the following: “are we making it easy / easier to do business with us?”

You could be surprised how little things make a difference, and how many organizations miss opportunities to care for, nurture, and make it easier for partners to prioritize their offers. Because in the end, if you streamline the partner journey to sell your products, they will spend more time pushing your offers then that of other manufacturers who leave gaps in the partner/customer journey.

This is where you should leverage Experience Cloud to give your partners everything they need. The most basic functionalities to put in place are about finding documentation, both commercial and technical. Invoices, sales guides, specifications and other technical documents are a given in any portal worthy of the name.

From there you can expand far and wide. Does your business model favor the sharing of leads and opportunities? If so, you can give leads to your partners through the portal, or have them upload leads to you through the same place. Do you offer support services to your partners? Why not enable them to request support directly from your portal using a system of tickets?

Add B2B Commerce to your portal to sell to your partners with their specific account pricing, discounts and multipliers, without going through sales or customer service. The time they save and you save with a more efficient process can be reinvested on both sides to find new customers.

If you sell complex solutions, or that you give commissions to your partners, you can create custom quoting tools or calculators, and add them to your portal, to enable your partners to get the right numbers by themselves.

Do not underestimate how big a difference it makes for partners to simply have on tap, whenever they want:

3. Breaking silos to better work with your channels

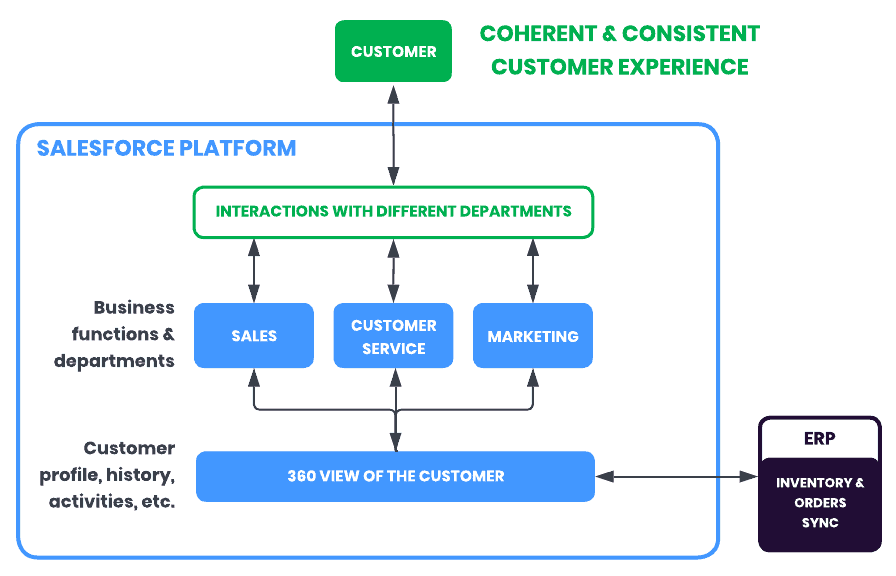

Beyond a partner portal, your various teams, covering different business functions (sales, service, marketing, operations) will still be interacting with your partners. And there is nothing more disappointing… even for a partner, then getting incoherent information and messages from different people at the same company.

We’ve all experienced it as consumers. Getting transferred from department to department, having to retell our story every step of the way. That is the WORST customer experience, and the last thing you want for your customers, resellers, distributors, value-added resellers (VARs), or specifiers.

In this context, a platform like Salesforce, which enables your teams to all work from the same customer information, updated in real-time, can literally break the silos of your company. All of your customer-facing departments access the same contact and account profiles, and are able to deliver the same coherent message to every customer. It doesn’t matter if the employee is in sales, customer service, or other business function: they have everything they need to deliver the expected customer experience.

And these capabilities apply to desktop and mobile. So the experience is maintained with on-the-road sales people, as well as traveling service crews, and trainers that visit customers, distributors or other channel partners.

Get customers and partners to give your their projections

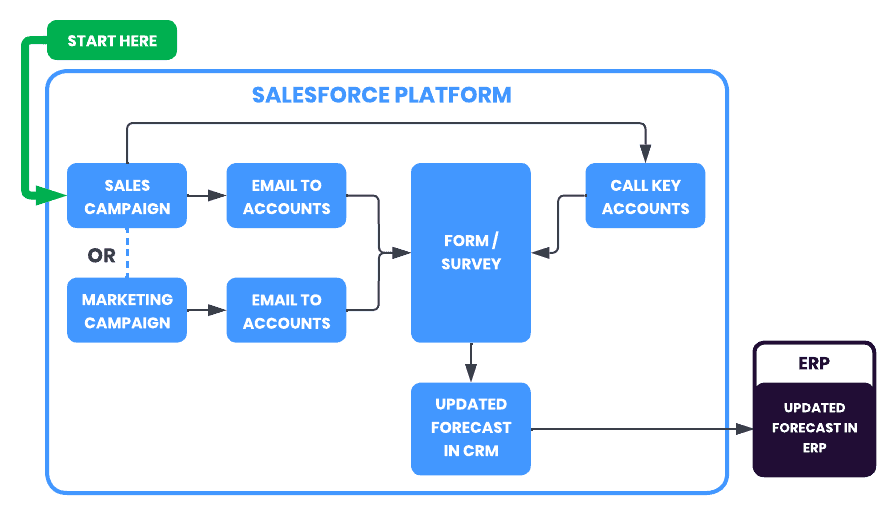

Since Salesforce is your one-stop shop for customer information, it is also the best place to gather information from them to help your teams optimize the supply chain.

Now, this can be done automatically or manually. In a realistic scenario, you would use both methods.

The automated way to do it, especially with your most engaged and reliable customers and partners, is to send them an email that directs them to an online questionnaire about their purchasing projections. This questionnaire can be in your Salesforce Experience Cloud portal, or using Salesforce Surveys, forms, or any equivalent that will feed information into your CRM.

The manual way to do it is to ask your sales or customer service reps to contact customers and get the information that way. This can be efficiently coordinated using the Campaign object to give a start and end date to the initiative, and a clear list of who to contact to each rep. In every case, you want your staff to input the information in the CRM as well.

From there, you can share these updated and curated projections with your operations teams. This is how your Salesforce Manufacturing Cloud CRM can be used to structure and launch a data collection campaign to assist your organization in navigating a disrupted global supply chain.

4. Feedback and data to improve channel management

Feedback and data are the raw materials with which you can identify what to improve, and how to improve your business. With the added complexity of multiple channels, good data becomes even more valuable as a guide, point of reference, or indicator to help the decision-making process.

Your CRM collects and keeps all your historical data for all your customer, partner and channel relationships. There are many benefits to this. First, your business is less impacted by turnover, because the people grabbing the relay have access to all the information about every contact and account and more. They are therefore better equipped to maintain the level of service customers were getting from employees who “knew them”.

Second, you have a clear 360-degree view of the present, from new leads, to opportunities that just opened or closed. This enables partner or channel managers to see the status of their KPIs in real-time and act accordingly. This also enables managers to use the same data to support, reward or correct course with their teams, and update their strategy if needed.

Finally, you can visualize this data, compared to previously observable trends to make and update your projections. You can also go further, beyond traditional reports and dashboards, and use Salesforce’s artificial intelligence module, Einstein AI, to give you insights on what it predicts will happen on key leads, opportunities and other business variables.

With the visibility provided by a robust and customizable CRM, you can do all this at scale regardless of how many channels you are using to go-to-market.

We strongly encourage all businesses to identify what is broken or could be improved, A/B test different solutions in pilot projects or circumscribed to small teams, and use the resulting data to double-down or try the next possible way to improve their business and processes.

5. Cross-selling across product lines and business units

Many manufacturers are split internally by product lines or business units. These divisions may have grown organically, or be the result of merger and acquisitions of other companies with different product lines.

Most executives will tell you that developing cross-selling is an objective of a large percentage of acquisitions. But for various reasons, many will also tell you that the expected result rarely materializes.

One of the pillars of making it work is to have the information from all business units, products, and acquisitions in one place: your CRM. All the accounts, the contacts, the purchasing history, the product catalogs, the pricebooks. That is the foundation needed upon which to launch a real-cross selling strategy.

From there you can design the sales paths, guidance, automations and other components that your teams will be able to follow and rely on to execute your cross-selling plan.

Overall, the value that you can generate for your channels using Salesforce for Manufacturing projects is almost unlimited. At SOLJIT, we can help you implement a fully customized Salesforce solution for the Manufacturing industry that will align with your strategic business objectives. If you have any questions regarding our services, click the button below to send us a brief message!

Order and delivery of quantity over time

In the B2B space, depending on what type of product or solution that you sell, regular customers and distributors may need to reorder products every month, quarter or year.

For this specific use case, manufacturers can configure their Salesforce B2B Commerce transactional e-commerce site to support the order of quantities over time.

This typically requires that your ERP is already integrated with Salesforce and that data about inventory and/or production planning is exchanged between the two systems.

From there you can enable customers to order different quantities of products that will be delivered over time, or at specific times, based on their own projected needs, or your production and delivery capabilities.

By giving visibility to your customers about inventory over time, and enabling them to order within those parameters, you de-risk their own supply chain and/or project timeline.

Offering this level of functionality to recurring customers is a great way to differentiate yourself from the competition through a value-added customer and partner journeys. And the best way to achieve this result is via a customized Salesforce solution for manufacturing projects.

Quoting in Salesforce

There are many ways to streamline the quoting process for your sales teams and partners using the Manufacturing Cloud Salesforce solution.

At the most basic level, you can import your products, price books and currencies within the standard objects of the platform. From there, the next step is typically to use document templates to generate quotes from these items based on what your sales rep has selected for that opportunity. You can also integrate electronic signatures to the document if you require your customers to sign them. This simple setup can be complemented by other standard automations configurable in the platform.

Since companies using Salesforce for the Manufacturing industry often have more complex offers, bundles, solutions, warranties, and even installation or maintenance services, you can use more powerful tools to meet your business requirements.

The Salesforce CPQ (configure, price, quote) module is widely used by manufacturers and solution providers to address these use cases. It enables your sales team to produce quotes faster even with the added complexity mentioned above. This also applies to manufacturers who have 100s, 1,000s or 10,000s SKUs.

For a deeper dive on CPQ features, please refer to our other dedicated CPQ content.

Looking at the entire picture, it is important to realize that Salesforce for Manufacturing projects is much more than just a CRM. It is a complete, scalable and customizable platform that can be transformative for your entire organization.

Whether you are looking for your first Salesforce implementation, or you want to improve your existing Salesforce instance, SOLJIT is your trusted partner to achieve your manufacturer CRM objectives.

Call us now at 1-877-276-5548 for a free consultation!

Most of this article has focused on how specific solutions can be implemented to answer the needs, or add value to manufacturers. But within the realm of digital transformation, the topic of mindset should not be forgotten. In many instances, mindset is the actual starting point for transformation, and should come first for many organizations that feel stuck in analysis paralysis.

Let’s discuss the mindset attributes to adopt, and the mind traps to avoid, to get the most from your Salesforce for Manufacturing projects.

Mindset

Start now, with simplicity

Avoiding analysis paralysis simply means starting now. Simplicity means customizing your CRM one step at a time. Not everything has to be done all at once. As a colleague would say: “don’t try to boil the ocean”.

We typically advise to identify what is your first or next MVP (minimal viable product) in terms of features or functionalities that your team will be able to use, and go live with that MVP.

The 80-20 rule

Not all use cases necessarily need to be addressed from the get go. The 80-20 rule is a good point of reference on this topic. What are the main use cases that generate 80% of your business? Make sure your CRM supports them. The remaining 20% can often be handled incrementally after the initial go live.

A very well known manufacturing CEO says that the most common mistake engineers make is to optimize something that shouldn’t exist. Whatever use case shouldn’t exist, or could be done away with, is clearly part of that 20% that shouldn’t stop you or your teams from going live with your Salesforce CRM.

Day-to-day efficiency

Big efficiency gains can be made by focusing on manual tasks that are done by your employees on a daily or weekly basis. If you automate tasks that take 1-hour per week for 100 employees, you just saved, or made, roughly 5,000 hours for your company.

Things as simple as automated reminders, task creation, template creation, quote generation, electronic signatures, etc. At scale, they can represent huge gains, and improve the employee experience for your employees.

Feedback & Improvement

When implementing and customizing a CRM for your company, your employees are also your customers. You should approach the project with the same care as if you were designing a customer journey. This implies involving them in the process, and getting first-hand feedback from them throughout.

From this feedback, you are encouraged to use the flexibility of Salesforce for manufacturing projects to make the needed adjustments, and deliver them as fast as possible for your teams. Why? For several reasons.

First, the platform allows you to make changes quickly, and in most instances, without any code. Second, it will increase the motivation and adoption of your staff if they see the company is listening, reacting and implementing changes based on their feedback. That might actually be as important as anything else to feed company culture in a positive way.

Mind traps

Going with a big-bang approach

Trying to do everything at once and solving every corner case is definitely not recommended. This bad habit of many companies will just slow down the pace of improvement of the organization. It results in project scopes that are too big and never get delivered.

Modern platforms like Salesforce can be configured incrementally and improved over time, to avoid these types of issues. Rollouts can be done in phases so users get engaged with the platform earlier, and subsequent phases create a momentum of continuous improvement for the entire organization.

Your business is unique… and it isn’t

It’s true, your business is unique. But that shouldn’t be used as an excuse to go against best practices. Yes, customize your CRM for what is mission-critical to your business. Otherwise, try to stay within the standard features and architectures of the platform, so you don’t complexify your project for no reason. This will also ensure that your solution will be easier to maintain over time.

Automate the little and big things, so people can unleash their human potential

We often see businesses with disjointed systems, and employees working manually in spreadsheets and tools from another era.

Ultimately, the benefit of automation is to enable people to focus on value-added tasks that only they can do. Like meeting new leads, understanding their needs, converting them to customers, and building solid business relationships. Everything else that can be automated, should be.

Salesforce for the manufacturing industry can help your organization get there, reliably and at scale, with the flexibility necessary to adapt to your business needs and model.

If you are looking for an experienced partner to help you implement Salesforce for manufacturing projects, consider contacting us for a free consultation. SOLJIT has been a Salesforce Partner since 2013. We have helped 100s of businesses start or continue their digital transformation with the #1 CRM in the world.

Call us at 1-877-276-5548 or send us a message using one of our web forms.

Accelerate your continuous improvement